Cooperating with paper factories

Potential for networking material and energy flows

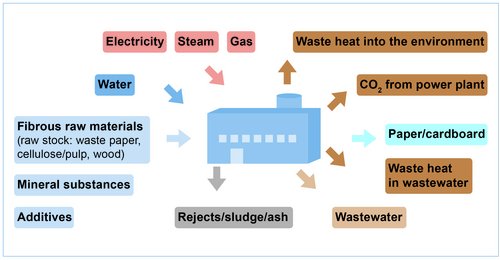

The production industry operates with high raw material efficiency in its German locations. Significant potential is often difficult to find. Yet working beyond company and industry boundaries still offers definitely interesting opportunities. Production sites of the paper industry, especially paper factories, are a good example of this.

For example, incineration ash from paper factories is suitable for use as a subbase material in road construction or for soil stabilisation. Fibre sludge can replace even more polystyrene and clay in brickworks. Bark and wood waste can be used to produce fuel pellets and fibreboards. The well-controlled processes of paper factories with their large mass flows provide a good basis for achieving reliably high quality in cooperation with the purchasers. The use of regenerative CO2 from residual material incineration for chemical and biochemical processes or the use of lignin to produce new (eco-) materials offer innovative potential.

Pape factories can also be customers for unused residual materials. For example, under certain preconditions, paper waste that could not be reused as material to date, such as service packagings or used paper towels, could be added to the cycle. Special paper products can be made, for example, out of tomato and other vegetable stalks or grass.

Surplus energy from paper production is available as a cost-effective energy source: Waste heat can be used for district heating or for production processes requiring heat, for example, drying. Surplus heat can also be used to produce cold for cooling in office buildings, data centres or food processing businesses.

In a project of the Bavarian Environmental Pact sponsored by the Bavarian State Ministry of the Environment and Consumer Protection and co-funded and actively supported by BayPapier, together with the Papiertechnische Stiftung foundation (PTS), bifa is currently determining such potential and ways of using them in an even better way.

![[Translate to Englisch:] Placeholder](/fileadmin/_processed_/f/4/csm_Header_Presse_d565a61df7.jpg)