Recycling of foundry dusts

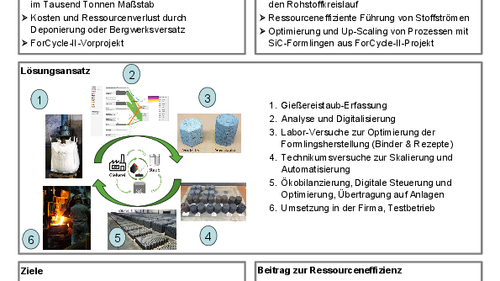

The sub-project of the ForCYCLE II project network focuses on the development of methods for the efficient use of resources and recycling of foundry dusts.

Foundries produce large quantities of iron-containing dusts every year. To date, the dusts have often been landfilled or recycled at a low level. Economic potentials are not yet fully exploited, resulting in high costs for disposal.

Resource efficiency through the production of SiC compacts

A wide variety of alloying agents are used to treat molten metals in foundries. Alloying agents containing silicon serve to silicify the melt during the melting process. If they are added at a later stage, they are referred to as preconditioning or inoculation of the melt. They are used to adjust the microstructure during solidification in order to achieve optimum mechanical properties of the cast product. The material used is usually ferrosilicon or silicon carbide, which is pressed into cement-bonded mouldings for use in cupola furnaces.

The company GPS SiC Keßl GmbH Co. KG is a producer of SiC-based mouldings, which are used by foundries for silicification. Within the scope of the project, in cooperation with GPS SiC GmbH & Co. KG, it is being investigated whether and how accumulating dusts can be used as a silicon supplier and as a raw material supplier for metals.

The project is funded by the Bavarian State Ministry for the Environment and Consumer Protection as part of the ForCYCLE II project network.

![[Translate to Englisch:] Placeholder](/fileadmin/_processed_/f/4/csm_Header_Presse_d565a61df7.jpg)