Yields in the recycling process chains

Only that which is actually returned to the cycle provides ecological and economic benefit

Precious metals, special metals, carbon fibres: Large potential values in waste are often enticing. They can, however, only be used if the material is not lost on the way from the production of waste to the recovery of marketable products.

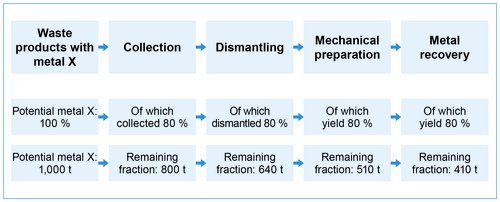

In fact, in most cases, only part of the waste is collected in recoverable form. After that, further quantities are lost in each pretreatment and treatment step. In particular, if waste has to be collected in many production sites and tend to contain only small concentrations of the target materials, these losses are mostly considerable. For example, if the metal recovery process chain contains four steps, each with 80 % yield, at the end only around 40 % of the metals are actually recovered. Only this quantity can also make a positive contribution to the ecological and economic balance of the recycling.

In the development and evaluation of recycling processes it is therefore important to examine the whole process chain, from collection through to final recovery. Only in this way is it possible to estimate the actual benefit realistically. This is also the only way to identify parameters that can make a significant contribution to increasing the yield.

bifa is using material, energy and value stream analyses to examine added-value chains in existing and planned recycling processes. bifa evaluates the results economically and ecologically to identify effective parameters. Analysis experience from projects for numerous clients in all kinds of different sectors such as electrical and electronic products, carbon fibres, plastics and biowaste provide a good basis to start from.

![[Translate to Englisch:] Placeholder](/fileadmin/_processed_/f/4/csm_Header_Presse_d565a61df7.jpg)