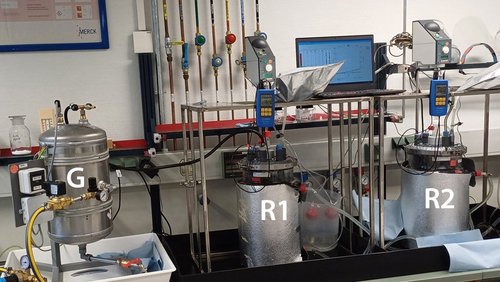

Laboratory reactors for the in-situbio- methanisation of synthesis gas and hydrogen

Eco-efficient, process-integrated sewage sludge utilization

As part of the BMWK-funded joint project Eco-PIK ‘Eco-effi-cient process-integrated sewage sludge utilisation’, bifa is investigating the biomethanisation of synthesis gas and hydrogen.

To simulate the digestion towers of municipal sewage treatment plants, laboratory bioreactors are operated under practical conditions with raw sludge as a substrate. The synthesis gas produced during the thermochemical conversion of sewage sludge pellets (sub-project of the Blue Energy Group) is used as a co-substrate. Hydrogen is also dosed for extensive biomethanisation of the carbon oxides (CO, CO2) of the synthesis gas and the carbon dioxide of the digester gas. This produces a product gas whose methane content is of natural gas quality. The yield of bio-methane is increased by a factor of around 4 compared to conventional sludge digestion.

In addition to energy recovery from the product gas (e.g. in an optimised micro gas turbine; sub-project of Augsburg University of Applied Sciences), it would also be possible to feed it into the natural gas grid and/or use it as a biogenic raw material. Since the in-situ biomethanisation of synthesis gas and hydrogen has been realised on a laboratory scale, the influence of the gaseous co-substrates on the microflora of the methane-forming bacteria is currently being analysed using molecular biological methods.